What is it for?

We intend to use this page as a form of discussion on engineering designs and drawings - this is just one of the many methods - feel free to use any. Hopefully this helps.

engineering design

Method possible:

1. Bottom-Up Design method

design method where the design starts from a few individual components, gather them to build up and form an assembly.

components + components –> sub assembly + sub assembly –> assembly

2. Top-Down Design method

design method where the design start from a component and from that component it build up and develop into a assembly

components (develop further) –> assembly level

depending on needs, one may opt either to approach the design

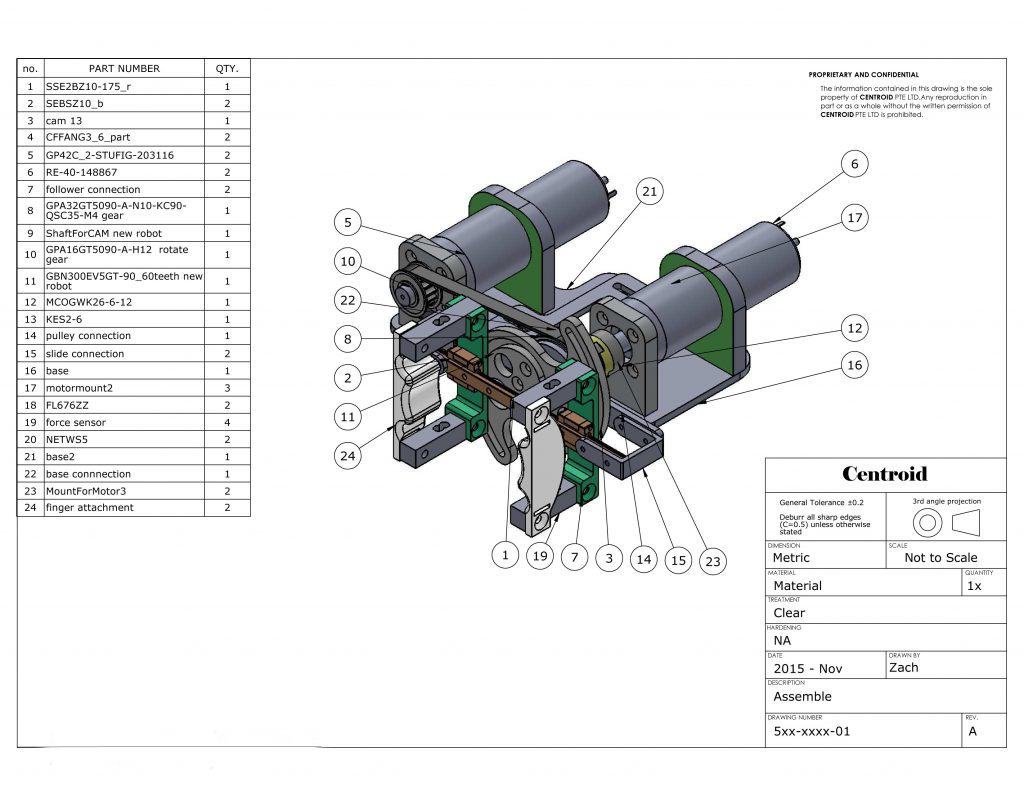

Engineering Drawing - Assembly Drawing

An assembly drawing is a drawing that made up of all the various individual parts.

In an Assembly Drawing you will find mainly:

1. Bill of Materials (BOM) describing the individual part and quantity

2. Numbering system that associate the BOM to the part

Do know that these Individual Parts are either fabricated or purchased part.

For example, fabricated part would be like item 3, CAM; item 24, Finger Attachment, etc..

And, example of purchased part would be item 6, motor; item 10, rotate gear; etc..

Only fabricated part that require fabrication needs to have a detailed drawing. Purchased part usually does not require any detailed drawing unless the part require some form of modification or machining.

(Distinction between Purchased part drawing which either get it from manufacturer webpage or develop by you to that of Detailed drawing is in the ‘detail’.)

assembly drawing

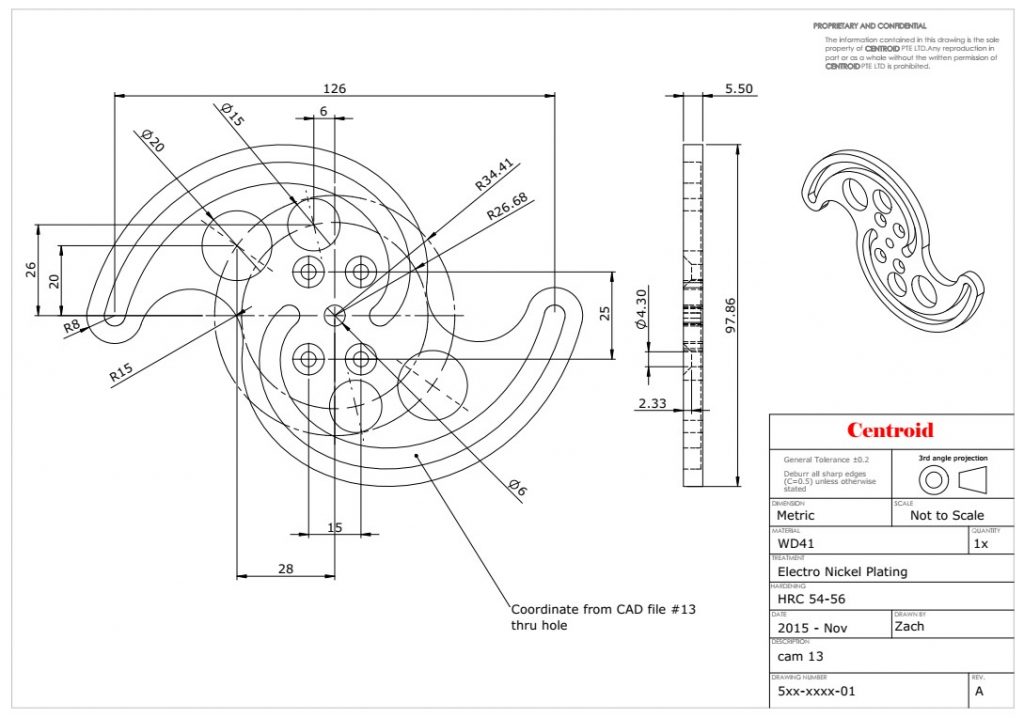

Engineering Drawing - Detailed Drawing

The detailed drawing is the drawing that usually end up on the production floor. This is where the machinist will use it to fabricate the part out. It’s the blue-print of the fabricated part.

In a Detailed Drawing you will find mainly:

1. Part dimensions and with their tolerance required

2. Type of material

3. Quantity

4. Treatment

5. Any note that could further help to clarify